Every whiskey distillery produces a byproduct known as stillage—the leftover mash after distillation. Traditionally, distilleries have disposed of this waste in various ways, such as selling it as animal feed or simply discarding it. However, with growing sustainability demands and stricter environmental regulations, distilleries must reconsider where their waste goes.

One company tackling this challenge head-on is Global NRG, a renewable energy firm that converts distillery waste into biogas. By taking stillage and turning it into usable methane and CO2, they offer distilleries a seamless, cost-effective way to improve their environmental impact without disrupting operations. I recently spoke with CEO Chris Negus about how Global NRG is helping whiskey distilleries reach their sustainability goals.

The Growing Problem of Stillage Disposal

While stillage may seem like an innocuous byproduct, improper disposal can lead to significant environmental consequences. In the U.S., for example, distilleries have faced hefty Environmental Protection Agency (EPA) fines when waste has been mismanaged. Even when stillage is given to farmers for animal feed, there’s no guarantee it won’t be improperly disposed of, leading to water contamination and other ecological risks.

“Some distilleries have faced large EPA fines because their stillage was given to a farmer who then discharged the excess into a watercourse,” explains Chris Negus of Global NRG. “As far as the EPA is concerned, the waste remains the responsibility of the distillery, not the farmer.”

In the U.S., distillery waste management presents a significant opportunity for innovation. While anaerobic digestion is well-established in parts of Europe, and distilleries such as Rabbit Hole implement sustainable waste management systems, some American distilleries still rely on traditional disposal methods that may not fully maximize the potential of their waste. Global NRG sees an opportunity to bring its expertise to the U.S. market, demonstrating how distilleries can turn stillage into a valuable renewable resource while improving sustainability and operational efficiency.

A Sustainable Solution: How Global NRG is Changing the Game

Global NRG offers a straightforward alternative: instead of allowing stillage to become an environmental liability, distilleries can hand it over to a company that turns it into a valuable resource.

“We take the stillage, process it through anaerobic digestion—essentially mimicking the four-stomach system of a cow—and produce biogas,” says Negus. “This results in methane that can be used as a renewable energy source and CO2 that is food and beverage grade.”

For distilleries, the benefits are twofold. First, Global NRG provides an easy, sustainable waste disposal solution—often at little to no cost. In some cases, they can even structure revenue-sharing agreements with distilleries, turning waste into an additional income stream.

Second, the process is highly scalable. Global NRG’s projects are built with expansion in mind, meaning distilleries that increase production can continue benefiting from the service without additional logistical concerns.

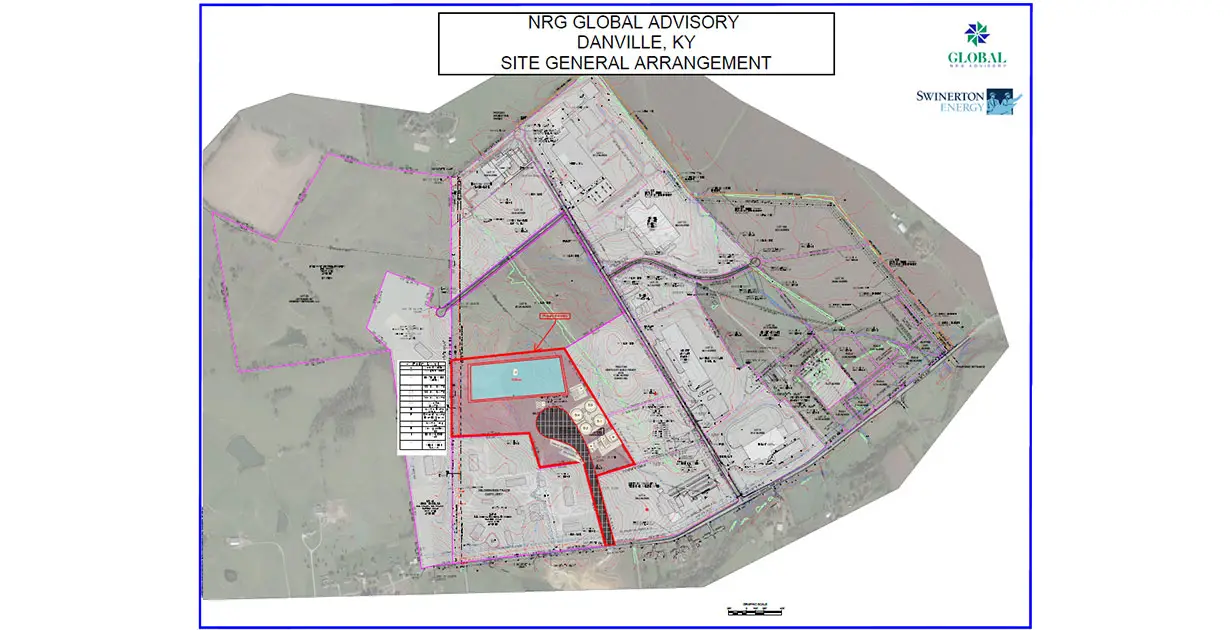

“We design our sites with sufficient land to expand,” Negus notes. “If a distillery increases production, we can expand to take more waste. We’re looking for long-term partnerships, not short-term fixes.”

The company already has established contracts with distilleries in Kentucky and Indiana, as well as some plants in Scotland, and a project underway in Danville.

Beyond Energy: The Full Environmental Impact

The advantages of Global NRG’s process don’t stop at renewable gas. The remaining byproducts from anaerobic digestion create a nutrient-rich organic fertilizer, which can be returned to farmers. This reduces the reliance on synthetic fertilizers, which are a significant source of CO2 emissions.

Additionally, by integrating waste collection into distilleries’ existing schedules, Global NRG ensures minimal disruption. The company works with local logistics providers rather than introducing new transport networks, ensuring that communities and businesses already serving the distilleries continue to benefit.

“We’re not looking to replace local sustainability partners,” says Negus. “We want to work with them. If a trucking company has been transporting stillage to farms for years, why wouldn’t we work with them to bring it to us instead?”

A Simple Step Toward Sustainability

For distilleries, partnering with Global NRG is a hassle-free way to meet sustainability goals, comply with tightening environmental regulations, and potentially open up new revenue streams. With large-scale projects already in place in Kentucky and Scotland, the company is well-positioned to support distilleries of all sizes.

“This is about making sustainability easy,” Negus explains. “All we require is a long-term commitment of at least ten years. That way, distilleries have a guaranteed, low-cost waste solution in place for the long term.”

For distilleries looking to future-proof their operations, reduce environmental impact, and ensure compliance with regulatory requirements, working with Global NRG is an opportunity too good to ignore.

To learn more or explore partnership opportunities, distilleries can contact Chris Negus directly.

Read the full article at Turning Waste into Opportunity: How Global NRG Helps Distilleries Meet Sustainability Goals